Optical measurement in quality control

For quality assurance purposes, components are tested before they are used. The measured values obtained must be interpreted and compared with predetermined target values. This often requires complex mathematical calculations. If there is no suitable standard software or you want to have full control of the algorithms used, you need to perform the calculations yourself.

For quality assurance purposes, components are tested before they are used. The measured values obtained must be interpreted and compared with predetermined target values. This often requires complex mathematical calculations. If there is no suitable standard software or you want to have full control of the algorithms used, you need to perform the calculations yourself.

Example

Example

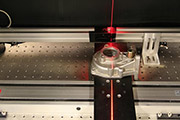

Components of a vehicle exhaust system are measured optically by means of laser triangulation for KÜBLER & ESSIG GmbH. From the measured values obtained, the centre point can then be determined for bodies of arbitrary shapes. Using mathematical methods, the calculations can even be performed on a Siemens S7 device driver.

For further information

LICHT UND BEWEGUNG (LIGHT AND MOVEMENT)

Testing complex components: Light section sensor, 3D image processing

KÜBLER ESSIG Journal 2013 (German) Page 3

INDIVIDUAL MEASURING EQUIPMENT SURPRISINGLY DIFFERENT

Scientific mission

KÜBLER ESSIG Journal 2011 Page 3

ECONOMICAL FOUNDATIONS

Mathematics offer amazing solutions

KÜBLER ESSIG Journal 2010 Page 3

Image sources:

Image 1: © Photonfocus AG

Image 2: © MICRO-EPSILON MESSTECHNIK GmbH & Co. KG